Making of a Floorcloth

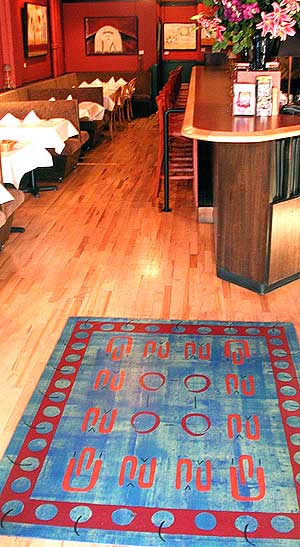

Floorcloths will even stand up to the heavy foot traffic in a busy restaurant!

Floorcloths are a functional art form dating back to the 1700s and recently rediscovered for their wealth of design possibilities and surprising durability.

Ideally suited to today’s hectic lifestyle, floorcloths are extremely practical for hallways, bedrooms, kitchens, foyers or family rooms. Simply wipe with a damp cloth to keep them clean. Mild soap can be added if necessary. You might use a thin underpad to guard against slipping, depending on the location and size of the floorcloth.

How are floorcloths made?

After years of testing various methods, Debra Gould perfected her own process for making a floorcloth that ensures a durable and flexible surface that won’t curl.

It takes at least 3 weeks to create a floorcloth. Heavy artist canvas is stretched and primed on both sides and a base coat is applied. Several colours may be layered over top with glaze to create a more three dimensional background for the design.

Once the design is complete and signed, the floorcloth is hemmed and multiple coats of varnish are applied. Then the floorcloth (or place mats) are allowed to cure for a week. The varnish protects the paint from yellowing or fading and provides a water-resistant and flexible surface that’s easy to clean.

The same basic techniques for this “art you can walk on” are used to produce place mats and table runners. Forget laundry and ironing – and these placemats won’t fade!

Her latest works also include fragments of poetry or quotations from such diverse sources as Rumi, The Talmud, inventors and scientists. Each letter is carefully traced and then painted onto the canvas — a process that can take a full day in the studio.